Palm Oil Refining Workshop

Over the past 30 years, the worldwide area planted to oil palm has increased by more than 150 percent. The palm oil contains rich vitamin A in the original (500-700 parts per million (PPM) and vitamin E (500-800 parts per million (PPM). Now in the market more and more customers have received the palm oil and it develops in a rapid speed. So Palm Oil Refining is one question most oil processing manufactures to resolve.

The main process of palm kernel oil production is described below.

Palm kernels are pre-treated by magnetic separators that removed metallic debris that might destroy your palm kernel oil press equipment. Then the kernels are sieved to remove sands, stones and other Impurities before cracking with inbuilt swinging hammers. The nuts are separated from the shells after cracking and prepared by heating before extracted with expeller press. The nuts are screwed through a metallic path (with pores) that decreases in diameter to the exit so that the oil is forced out of the side while the cake is collected at the tip of the screw.

Finally, palm kernel oil (PKO) obtained via mechanical means are usually filled with impurities that must be removed by further processing.

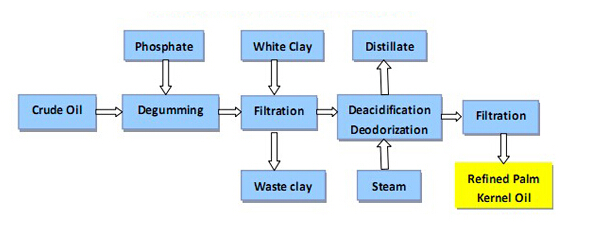

Oil refining is based on the different usage and requirements, utilizing the physical methods and chemical processes to get rid of the harmful impurities and needless substance in the crude oil, getting standard oil.

Equipment of Palm Oil Refining Process:

Degumming section:

Degumming is the first and basic step in the crude oil refinery plant, degumming process aims to removing the gum impurities in the crude oil to make it suitable for further refinery process, hydration degumming and special acid degumming are the two main methods.

Deacidification section:

The deacidification system uses versatile neutralization technology, which is developed to deal with oilseeds of different species and qualities in the oil refining plant, it can realize both degumming and neutralization processes by adding alkali, water and acid, then with FFA, crude phospholipids and moisture all removed, the oil and by products (soap foot, phospholipids) are separated.

Bleaching section:

The oil bleaching is also named decolorization in oil refinery processes. This process’s main purpose is to remove the product of oxidation, pigments, phospholipids, soap materials from the oil. In the oil refinery plant, this process can improve the oil color as well as supplies high quality oil for the deodorization process.

Deodorization section:

Deodorization section is very crucial in edible oil refinery plant in first grade oil production as it improves the flavor of the oil; the quality of deodorization equipment has great effect to the oil quality.

50T/Day Soybean Oil Production Line Delivery to South America

50T/Day Soybean Oil Production Line Delivery to South America

Ethiopia to get giant edible oil plant

Addis Ababa: June 17,2015 – A new edible oil plant said to be the largest in terms of production capacity will be opera

2TPD Rapeseed Oil Refinery Equipment in Algeria

This small oil refining equipment was set up in Algeria, the raw material is rapeseeds and the daily capacity is 2T/D.