Palm Oil Processing Plant

Crude palm oil processing plant is a very nice project in those of palm planting area and regions such as African and Southern Asia. Among all palm planting area, Nigeria, Indonesia and Malaysia are important planting region of palm. Crude PALM OIL PROCESSING PLANT is not a simple oil expeller, but contains an entire palm oil process production line.

Crude palm oil processing plant is a very nice project in those of palm planting area and regions such as African and Southern Asia. Among all palm planting area, Nigeria, Indonesia and Malaysia are important planting region of palm. Crude PALM OIL PROCESSING PLANT is not a simple oil expeller, but contains an entire palm oil process production line.

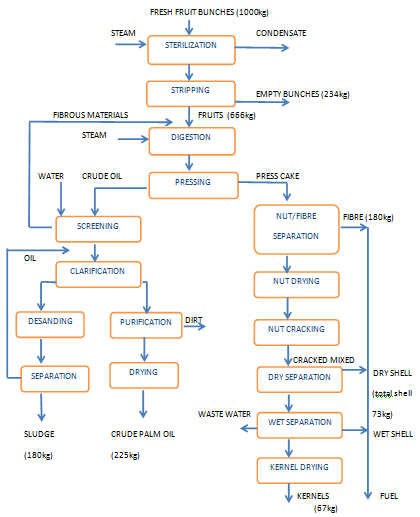

1.palm oil processing plant-Pretreatment Section:

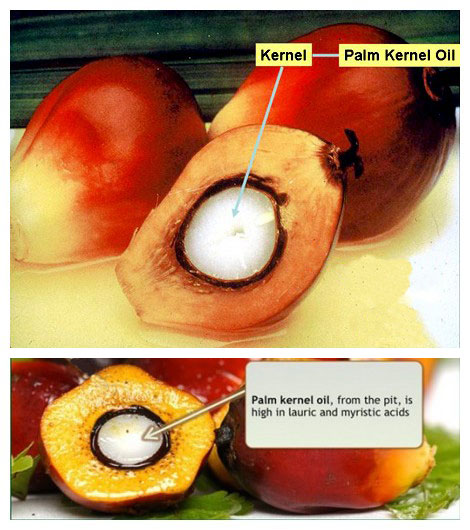

Sterilizing section: Fresh palm fruit bunch are airtight sterilized in sterilizer. The purpose to prevent enzymes broken down, avoiding FFA content in oil further increase; Pretreatment peel, prepared for the follow-up processing; Pre-conditioning stone, reducing the damage kernel.

Picker palm fruit setcion: Remove the palm fruit from the bundle.

Boiling section Oil palm fruit first carry out cooking before pressed, fruit sterilized must be re-heating for the soft pulp, and damage pulp cell structure.

2. Palm oil processing plant-Pressing section:

The process adopts the special screw oil press, so the palm nut is out with the dregs without damaging.

3. Palm oil processing plant-Clarification section:

The crude oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carries out continuous settlement, the whole divided into two parts: Oil and sediment. Oil is filtered and through the pump pumped into the storage tank for storing; Oil sediment is filtered and dirt oil separation, oil processed is for the second settlement, dirt oil mixture process clarification separation, skim oil then carry out a second settlement, sewage pumps to sewage treatment pond for dealing with.

4. Palm oil processing plant-Palm nut treatment process/Centrifuge sieve

This process adopts the centrifuge siever to separate the nut and fibre and dregs.

5.Palm oil processing plant-refinery.

The crude palm oil from the palm will be pumped into oil refinery units to produce cooking oil at various grades. We adopts advanced physical refinery technology, which is most methods for new CPO factory now.

The main operating process is including sedimentation/filtering, degumming, decolorization (bleaching), neutralization (removing free fatty acid) & deodorization with distillation, especially the fractionation process is necessary, which could get different liquid oil and fat. Different combination of steps and the treating degree of each step result in different grade cooking oil and salad oil.

6.Palm oil processing plant-fractionate.

Fractionation of palm is important for getting different grade oil.

(1)Pre-processing.

Oil is better to be stored in a storage tank with constant stirring so as to avoid solid fat sedimentation and to ensure even crude oil to be sent to the plant. The temperature inside the storage tank should be 10°C~20°C higher than the melting point of the oil fat. Before the RBD palm oil been sent to the crystallizer, it has to be processed through a plate heat exchanger. This will heat the oil from 45°C to 70°C approximately, fully melting the solid oil.

(2)Crystallization and crystal growing.

The temperature of oil slurry and water is measured and recorded. The water temperature is controlled by gradual program using a micro-information processor to ensure the crystallization in the pre-arranged cooling curves.

The time of crystallizing is adaptable due to required quality of the product. This can be conducted by the curve line in the computer in the control room. Extra big cooling area guarantees the maximum flexibility and easy handling. The crystal obtained is even and filterable with stable structure.

(3)Filteration.

Oil slurry gradually enters into the space though the filter plate piece by piece. Liquidfat flows out by the corrugated channel of rubber membrane through the filter fabric and then enters the soft fat tank by closed pipe outside the filter’s frame, solid fat is leftover. When filter is stuffed with solid fat, it stop input the crystallized palm oil and diaphragm will inflate under high pressure (usually condensed air) to press the solid fat. Thus, the remaining liquid fat can be clearly removed. After been pressed, recycled oil slurry is conveyed into purge oil tank for temporary storage, the entrance of oil slurry be purged by condensed air. Opening the filter to releasing filter cakes is followed after releasing the pressure of the filter. Slipping chain with a hook moves along the 2 girders making the diaphragm to shift piece by piece so that filter cake can drop into the melting oil slot easily. The filter cake afterwards will be heated to melt and then be pumped into the solid fat storage tank. Filter fabric should be cleaned periodically by hot liquid fat and the solid fat should be melted.

50T/Day Soybean Oil Production Line Delivery to South America

50T/Day Soybean Oil Production Line Delivery to South America

Ethiopia to get giant edible oil plant

Addis Ababa: June 17,2015 – A new edible oil plant said to be the largest in terms of production capacity will be opera

2TPD Rapeseed Oil Refinery Equipment in Algeria

This small oil refining equipment was set up in Algeria, the raw material is rapeseeds and the daily capacity is 2T/D.