Corn Germ Oil Extraction Plant

The corn germ oil extraction plant designed by Wintone Machinery adopts advanced fine corn processing flow line design to produce grade corn flour, gits, germ and fine feeds with dry milling method, ensuring quality product up to national standard.The products are widely used in food, s ugar, beer and oil plants. The core equipments gain national patent.

Corn Germ Oil Extraction Plant Main Specification: 50~5000T/D

The corn germ mill extraction machine applies to corn germ, soybean, cotton seed, rapeseed, camellia seed, sunflower seed, rice bran, etc.

Main Equipment: rotary multi cell extractor with stainless steel gate or drag chain extractor, D.T.D.C desolventizer-toaster, total negative pressure evaporator, paraffin recovery equipment, etc.

Full continuous corn germ oil extraction plant main parts:

Pretreatment & Prepress:

a. Cleaning device: remove the raw material peanut in various impurities, such as: iron,

stones, clump, such as the plant leaf, clean up till impurity content does not exceed 0.2%.

b. Crushing machine: peanut is crushed into 6-8 pieces. In order to meet the requirements

of crushing, the peanut is suitable for crushing with the moisture of 7% to 12%.

c. Softening process:the purpose of softening is to adjust the moisture and temperature

of oil, and make it soft.

d. Flaking process: rolling raw material into flakes, and the purpose is to increae surface

area, destroy the peanut cell tissue, shorten the way of oil out from cake.

e: Cooking process: use steam cooking, inject direct steam and cook the flakes to meet the requirement of oil press.

f. Pre-press: press the flakes to leave about 16%-18% in the cake. The cake will go to extraction process.

Oil Extraction process:

1. Solvent pumps: continuously spray solvent to the rotary-type extractor

2. Roary extractor: Spray and soak the pre-pressed cake with solvent so that oil fats can be diss-olved in solvent(form miscella). After processing, you can get wet meal and miscella (mixed oil).

3. DTDC: usd to separate the solvent from the wet meal.

4. Miscella tank 1st: pump the miscella (oil with solvent) in to the miscella 1st , then add saline

water to it.

The phospholipid in the miscella will react with the saline water, at last the reactant precipitate, reaching the goal of purifying.

5. Miscella tank 2nd: the purified miscella will be pumped into it.

6. Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.

7. Condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

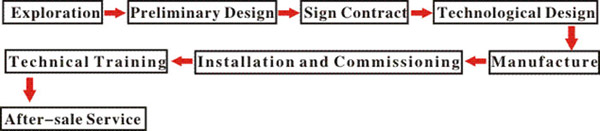

Wintone Machinery is mainly engaged in oil processing engineering R & D, oil equipment manufacturing, installation, commissioning and training service. Wintone machinery has rich experience in oil mill press installing and producing, scientific management methods, complete quality assurance system, which guarantee us to finish our each oil processing project reliably.

We can provide design, manufacture, installation, calibration and after service of corn germ oil extraction line.

50T/Day Soybean Oil Production Line Delivery to South America

50T/Day Soybean Oil Production Line Delivery to South America

Ethiopia to get giant edible oil plant

Addis Ababa: June 17,2015 – A new edible oil plant said to be the largest in terms of production capacity will be opera

2TPD Rapeseed Oil Refinery Equipment in Algeria

This small oil refining equipment was set up in Algeria, the raw material is rapeseeds and the daily capacity is 2T/D.