Peanut Oil Refining Equipment

Main Specification: 30~1500T/D

Peanut oil refining equipment/plant Working process:

(1)Pump crude oil into refining tank and heat with conduction oil, and the temperature will reach about 70°C-80°C after one hour.Add acid or alkali to separate according to the acid value. After one hour's processing and 4-6 hours deposit, then convey soap stock to storage tank.

(2) Pump refined oil into decoloring tank. When it is up to 90-110 °c after one hour's heating, add clay into tank for 20 mins' processing.Then clay and oil are separate by filter.

(3)Put discolored oil into deodorization tank with vacuum pump. Heat and process with steam for odor removal. After filtering, you will get final oil product.

Peanut oil refinery workshop applies to peanut oil refinery.Peanut oil refining equipment/machine Main equipments:

1.Neutralizing pot: for acid refining, alkali refining and washing;

2.Decolouring pot: for bleaching the oil and removing the pigment;

3.Deodorization pot: for remove the odour of the oil; (stainless steel)

4.Heat-conducting oil furnace: providing the vacuum required by declourizing and deodorizing;

5.Air compressor: for drying declourizing clay;

6.Filter press: for filtering clay7.;

Steam generator: for generating the required steam of deodorizing distillation.

The characteristics of our peanut oil refining technology are as following:

(1) Super-wet degumming;

(2) Carclazyte frequency dosing automatically;

(3) Negative bleaching total mixed;

(4) High-vacuum steam ejection deodorization;

(5) Fully auto-control system.

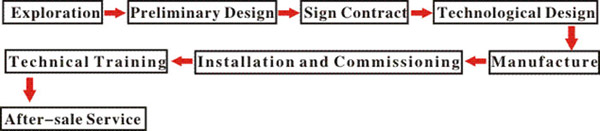

We can provide design, manufacture, installation, calibration and after service of peanut oil refining workshop.

50T/Day Soybean Oil Production Line Delivery to South America

50T/Day Soybean Oil Production Line Delivery to South America

Ethiopia to get giant edible oil plant

Addis Ababa: June 17,2015 – A new edible oil plant said to be the largest in terms of production capacity will be opera

2TPD Rapeseed Oil Refinery Equipment in Algeria

This small oil refining equipment was set up in Algeria, the raw material is rapeseeds and the daily capacity is 2T/D.